In Russia, they announced the development of the first domestic lithography installation, which will be able to manufacture 7-nanometer chips. To understand the size, almost 1.5 million modern transistors made using the 7-nanometer process technology can be placed on a hair cut. 6 years were allotted for development, the specialists of the Institute of Applied Physics of the Russian Academy of Sciences (IPF RAS) in Nizhny Novgorod will be engaged in the creation of the Alpha Machine. This was reported on the website "Development Strategy of the Nizhny Novgorod Region".

The publication rightly notes that the lithograph is the most complex and expensive element of any microelectronic production. It also says that a lithograph for making 7nm chips will appear in Russia by 2028. It is planned to create an installation on an X-ray source of radiation (and not ultraviolet), which requires the absolute smoothness of the elements up to 1 angstrom – this is one ten-millionth of a millimeter.

“Compared to, for example, lithographs from ASML, the world's leading manufacturer from the Netherlands, in the Nizhny Novgorod model, the radiation source is many times more compact and cleaner in operation, which ultimately significantly affects the cost, size and complexity of the equipment. The optical system of the demonstrator, produced at the IPM RAS, generally surpasses all analogues that exist in the world today, ”the publication says.

At the moment, only a few companies can produce 7-nm transistors in the world – these are Samsung, Taiwanese TSMC and Chinese SMIC, working on the equipment of the Dutch company ASML. The Russian installation will be 1.5–2 times more efficient than the Dutch one, according to a publication in Nizhny Novgorod, citing scientists.

ASML is the world's largest supplier of lithographic scanners, which are essential for the production of all semiconductor products. On October 15, it became known that due to US sanctions, ASML was halting equipment supplies to China. China has only just started making 28nm transistors, an aerospace chip engineer told The Insider.

In Russia, the situation with the production of semiconductors has been disappointing for many years. Of the domestic processors, there are only Baikals and Elbrus. There were samples of "Elbrus-2SM" on the 90-nm process technology. New processors, which were designed for the 28-nm process technology, were already ordered from the Taiwanese TSMC. Later, under the influence of the United States, Taiwan refused all orders for the Russian Federation. There are two enterprises in Russia that produce chips: Crocus Nano Electronics and Mikron. However, the limit is the 90-nm process technology, below this indicator no one produces anything.

According to the interlocutor of The Insider, six years is an unrealistic period. “We need five times more time, a hundred times more money. IAP is a well-known and respected research institute, but let’s say that China has been developing such technologies for ten years with virtually unlimited budgets, and there is no result yet, literally this year they mastered 28 nm, which is incomparably simpler than 7 nm.

Russia is also very far from creating chips directly, since this process requires not only the presence of lithographs, but also a lot of auxiliary equipment, for example, machines for making masks (stencils for lithography), and software is also needed. In fact, Russia now does not have the production of modern chips, as well as "machines" for their creation, even for the production of developer lenses on photoresist.

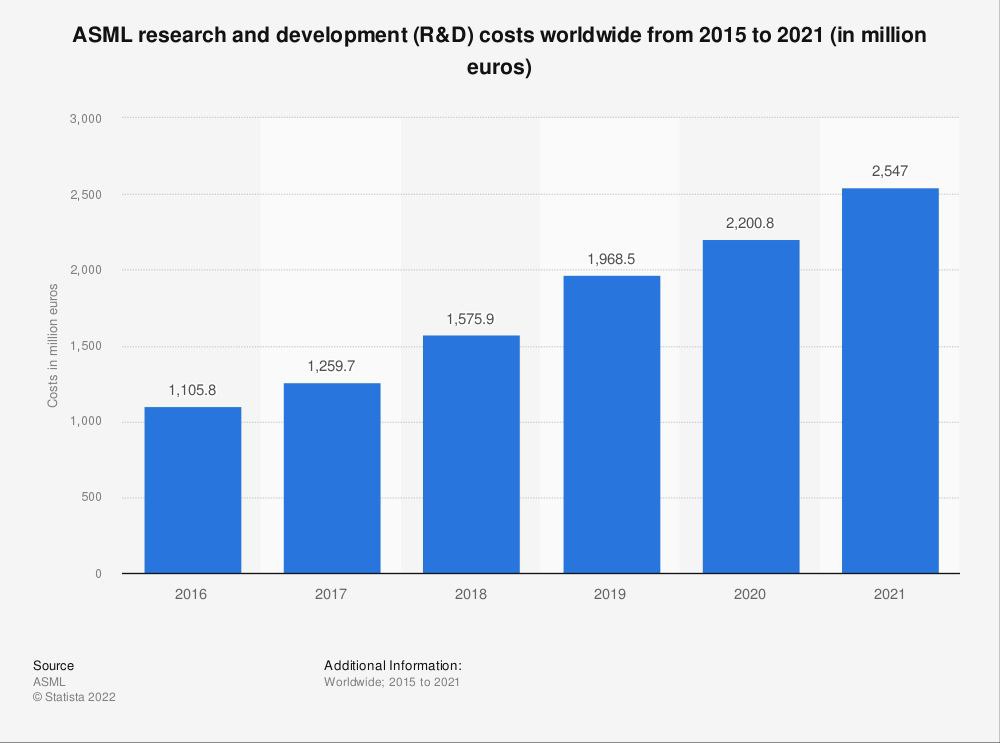

Both the production of chips and the production of lithographs are very expensive processes. The most expensive optics in lithographs. In 2021, ASML's R&D spending reached 2.5 billion euros per year. As of 2014, the development of EUV lithographs has already cost the company 14 billion.

In fact, the project can repeat the fate of the Russian medium-haul MS-21 aircraft, the production of which is promised to start in 2017, allocating billions of rubles almost annually. In 2013, Rosnano invested 40 million euros in Mapper Lithography, the main condition was "that the plant will be built in Russia," said the participants in the process. In 2018, the company was declared bankrupt, and the intellectual rights were bought out by ASML.